Air-cooled components quickly reach their maximum load when used in areas with high ambient temperatures or where there is a lack of cooling air. This results in disruption, power loss or even entire system failure. The problem is made worse by the increasing demand for higher power densities, which do not allow for sufficient surface area and, thus, cooling capacity.

However, REO offers a broad product portfolio of water-cooled inductive and resistive products allowing you to use high power components in even the most adverse and challenging of conditions. Water cooling makes it possible to use resistive components that are up to 70% smaller and ensures the best possible level of cooling, regardless of ambient temperature, excellent efficiency, and extremely quiet operation. This means that circulatory and forced cooling fans can often be entirely dispensed with.

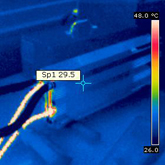

Another positive side effect is that the housing temperature is kept to a minimum and can often be lower than the ambient temperature. This provides protection if you touch the components, so can reduce the need for physical guarding and in addition adjacent components are not impacted by radiated heat losses either. Water-cooled components made by REO are therefore well-suited for use in the timber and textile industry or in explosion-proof environments.

The use of a water-cooling system not only enables excellent cooling performance but also allows optimal component temperature characteristics to be utilized, this means the performance and lifetime of the component is improved which helps to reduce the product lifetime costs.